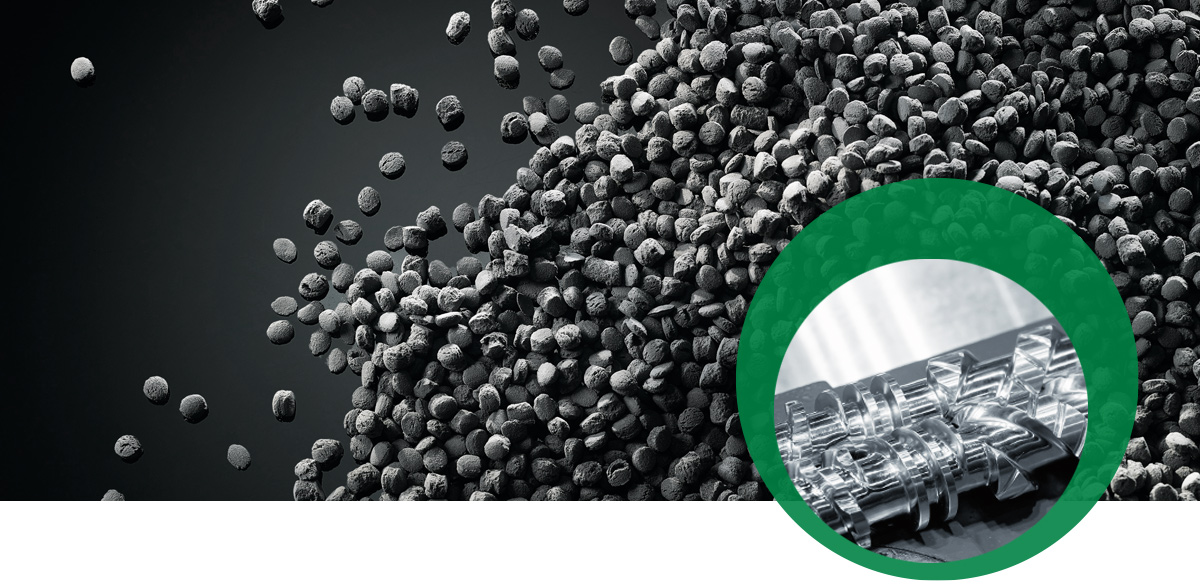

Our free-flowing, thermosetting moulding compounds are granulated plastics that chemically cure under the influence of temperature. During the moulding process, a three-dimensional network is formed that reliably prevents softening or melting of the material in the event of thermal stress. This ensures that the thermosets have a significantly different, unique performance profile compared to other polymer materials.

- thermal resistance for continuous, alternating and short-term peak loads

- dimensional stability and low creep tendency independent of temperature

- ability to withstand high levels of mechanical and electrical stress

- exceptional resistance to a broad range of chemicals, including fluids used in automotive and aerospace industries

- reliable flame resistance without drips of flaming particles and low smoke emission and toxicity in case of fire

| Thermal resistance | Dimensional stability | Mechanical strength | Electrical insulation | Tracking resistance | Chemical resistance | Hydrolysis resistance | Tribological behaviour | Crack resistance | Embedding of electrical inserts | |

| EPOXIDUR®

Epoxy resin moulding compounds |

●● | ●● | ●●● | ●●● | ●● | ●●● | ●●● | ●●● | ●●● | ●●● |

| MELOPAS®

Melamine resin & melamine/phenolic resin moulding compounds |

●● | ●●● | ● | ●● | ||||||

| SILICONE

Silicone resin moulding compounds |

●●● | ●● | ●● | ●● | ● | ●● | ● | ● | ||

| RALUPOL®

Unsaturated polyester resin moulding compounds |

● | ● | ●● | ●● | ●●● | ● | ●● | ● | ||

| AMPAL®

Melamine/polyester resin moulding compounds |

● | ●● | ●●● | ●●● | ● | |||||

| DAP & DAIP

Diallyl phthalate resin & diallyl iso-phthalate resin moulding compounds |

● | ● | ● | ●● | ●● | ● | ●● | ● | ● | ●● |

This table is not intended to be exhaustive. Our experts will be pleased to help you select the optimal product for your application.

Should your search for a product for your application not be successful, please do not hesitate to contact us. If required, we offer the possibility to design an individualised and tailor-made product together with you.

Customised solutions

We address the specific needs of our customers and can therefore offer products with an optimised performance profile. If necessary, we can offer our customers to adjust the material with highly specific properties in addition to the general advantages. These include maximum crack resistance, outstanding tribological behaviour and a high degree of heat conductivity with consistently excellent electrical insulation properties. We also supply products that form media-tight bonds to a large number of substrates. Processability in the low pressure range for a gentle encapsulation of sensitive electrical or electronic components can also be integrated. Of course, our thermosetting moulding compounds can also be used for hybrid technologies, by adopting corresponding material characteristics to various materials and substrates.

Ideally suited for a variety of application areas

Due to their exceptional properties, our thermosetting moulding compounds are extraordinarily well-suited for serial applications in:

- electrical installation, automation technology and energy supply

- microelectronics (PCB, SMD)

- rolling stock vehicles

- aerospace engineering

- automotive engineering, especially for power train, transmission and e-mobility

- health technology

- household goods

With RASCHIG thermosets, you can also rely on sophisticated production, machine and processing technologies at a fair and affordable price/performance ratio. In doing so, you profit both from well-established standard technologies for processing (injection moulding, transfer and compression moulding) and from the possibility of fully automated and economical processes with large cavity numbers and short cycle times.

| E-motors rotors/ stators | Electro-magnetic coils | Sensors, PCBs, micro-electronics | Health technology | Electrical connectors | Lamp sockets H-4 / H-7 |

Metal substitution | Electrical installation, energy supply | Electro-mechanical components | Household/ sanitary | |

| EPOXIDUR®

Epoxy resin moulding compounds |

● | ● | ● | ● | ● | ● | ● | |||

| MELOPAS®

Melamine resin & melamine/phenolic resin moulding compounds |

● | ● | ● | ● | ||||||

| SILICONE

Silicone resin moulding compounds |

● | |||||||||

| RALUPOL®

Unsaturated polyester resin moulding compounds |

● | ● | ● | ● | ● | |||||

| AMPAL®

Melamine/polyester resin moulding compounds |

● | ● | ||||||||

| DAP & DAIP

Diallyl phthalate resin & diallyl iso-phthalate resin moulding compounds |

● |