Would you like to receive information about our products and offers? We will be pleased to advise you on our range of products. Of course, we are also at your disposal with our know-how at any time for all further questions.

Material

We assist in the selection of materials and, together with our customers, select the appropriate moulding compound that best meets the application requirements. In principle, our moulding compounds have a modular structure, which makes customer-specific material adaptations extremely easy. In addition, our dynamic development department is at your disposal for material development. For each customer and application-specific development, material samples can of course be provided, which we are able to produce in our pilot plant on close-to-production lines if required.

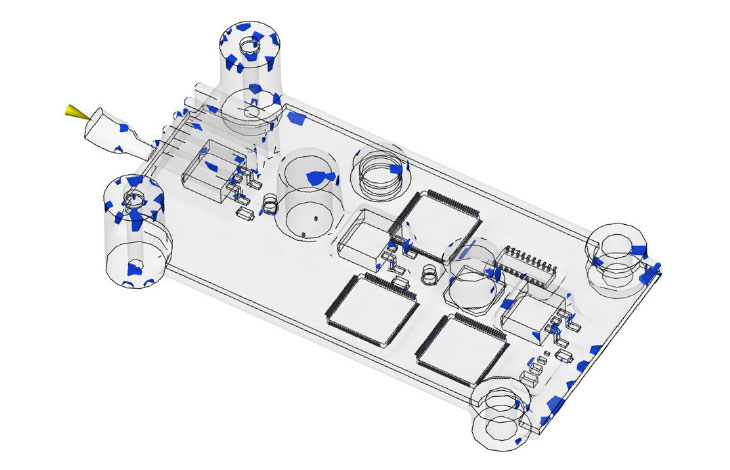

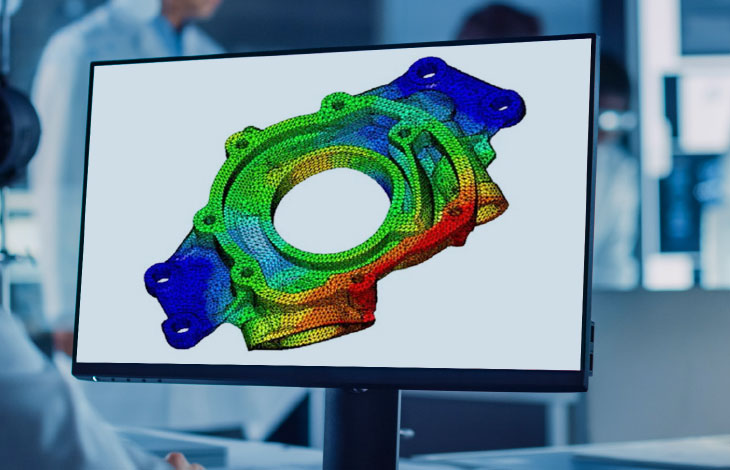

Stress-simulation

for binding line determination

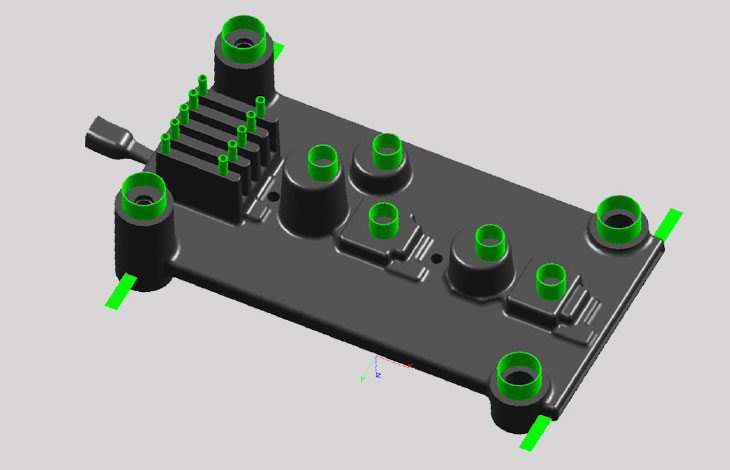

Prototyping / tool design

Optimisation of ventilation concept

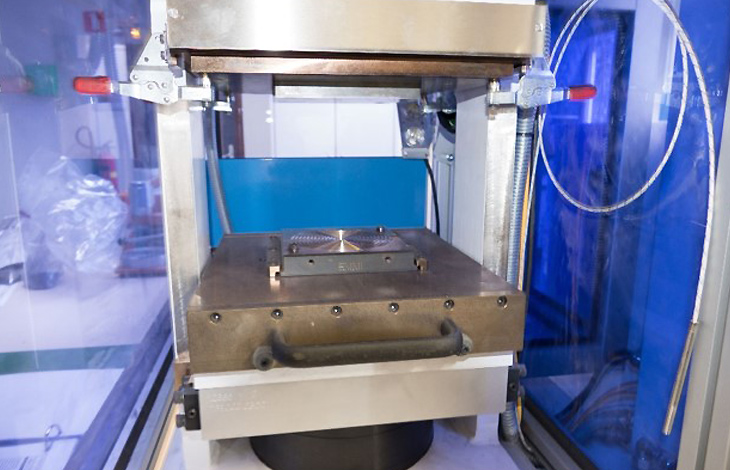

Tests

We carry out controlled material tests according to common standards for mechanical, electrical and thermal properties. In addition, we can also test the progression of properties under the influence of time and temperature and carry out storage tests in various operating fluids/chemicals to determine their resistance. For more specific tests we can also rely on our long-standing contacts to established and competent cooperation partners.

Most modern

test equipment

Material testing

according to common standards

Prototypes and components

We produce prototypes both in-house and in collaboration with our experienced cooperation partners for highly specific components. We would be pleased to advise you on the conception, selection, positioning and suitability of mechanical and/or electronic inserts.

Filling simulation

for demanding components

Application engineering service

and comprehensive support

Processing

You can rely on us for the determination of process parameters. We support you in the selection of process monitoring sensors, advise you on the design and also assist you in the implementation of process DoEs and processing trials. On request, we can also help you temporarily with processing in serial production.

Further services

If you need support in tool layout, design and construction or a consulting partner for handling, deburring, conveying and cleaning of inserts, you can also contact us conscientiously.

Of course, we also offer various training courses and workshops on topics such as processing, materials expertise or handling.