These are materials with inorganic fillers and reinforcing materials such as glass fibres, glass beads or mineral fillers/fibres. We also supply customised materials with special functional fillers to generate special properties such as thermal conductivity, tribology or low coefficients of linear expansion.

Product characteristics

Our epoxy resin moulding compounds have excellent properties for the highest demands. The coefficient of linear expansion (CTE) can be individually adjusted to your requirements in the range from 15 to 30 ppm. The products have excellent adhesion and thus media tightness to many substrates such as lead frames, PCB solder masks or even EPOXIDUR® pre-mouldings.

Their excellent resistance to many fluids and chemicals makes them particularly suitable for use in the automotive sector. The chemical resistance is given with many aggressive fluids, for example in the brake fluid DOT 4, all types of (bio)fuels as well as transmission fluids / ATF (ZF Lifeguard 8, Shell L 12108). The moulding compounds have an autoclave resistance of 3000 cycles at 137 °C. They also have a high thermal conductivity of up to 10 W/m*K while maintaining full electrical insulation. The temperature resistance of the encapsulated electronics is -60 to 175 °C at 3000 temperature cycles. The high dielectric strength of up to 60kV also allows very thin insulation thicknesses to be used. Due to the excellent mechanical and thermomechanical properties, crack resistance is still guaranteed.

We attach great importance to be conform with material compliance requirements, which we take into account constantly from development to serial production. In this way, we ensure that EPOXIDUR® materials meet all standards, do not contain any prohibited or declarable ingredients and are free from any hazardous substance labelling.

Our moulding compounds are approved for use in electrical insulation systems according to UL 1446 insulation class H / >180°C and are used in many corresponding applications. The continuous operating temperature is up to 210°C (20,000 hours) according to IEC 60216/T-1. UL Yellow Cards with UL94-V0 classifications are also possible. The products meet the ATEX requirements of electrical systems. They are biocompatible according to EN ISO 10993-5 (cytotox test).

| Temperature resistance | Isotropic properties | Dimensional stability | Tribological properties | Chemical resistance | Encapsulation sensitive inserts/ low pressure molding |

Crack resistance/ media tightness |

Thermal conductivity | Mechanical strength | |

| EPOXIDUR® EP 3162 E |

●● | ● | ● | ●● | ●● | ●● | ●● | ●● | |

| EPOXIDUR® EP 3161 E |

●● | ●●● | ● | ●●● | ●● | ●●● | ● | ● | ● |

| EPOXIDUR® EP 3163 E |

●● | ●● | ●● | ●●● | ● | ●● | ● | ●●● | ● |

| EPOXIDUR® EP 3580 T |

●● | ● | ●● | ● | ● | ● | |||

| EPOXIDUR® EP 3585 H |

●●● | ●●● | ●● | ● | ●● | ●● | |||

| EPOXIDUR® EP 3685 T |

●● | ●● | ●●● | ●● | ●●● | ●●● | |||

| EPOXIDUR® EP 3681 E |

●● | ●●● | ● | ●● | ●● | ●●● | ● | ● | |

| EPOXIDUR® EP 3781 E |

●● | ●●● | ● | ●● | ●●● | ●●● | ●● | ●● | |

| EPOXIDUR® EP 3585 S |

●● | ● | ● | ●● | ●● | ||||

| EPOXIDUR® EP 3582 S |

● | ● | ● | ● | |||||

| EPOXIDUR® EP 3581 L |

●● | ● | ● | ●● | ●● | ● | ● | ||

| EPOXIDUR® EP 3573 S |

● | ● | ● | ●● | ●● | ||||

| EP 3505 | ●● | ●● | ● | ● | ● | ||||

| EN 5004 | ●●● | ●● | ●● | ● |

This table is not intended to be exhaustive. Our experts will be pleased to help you select the optimal product for your application.

Should your search for a product for your application not be successful, please do not hesitate to contact us. If required, we offer the possibility to design an individualised and tailor-made product together with you.

Applications

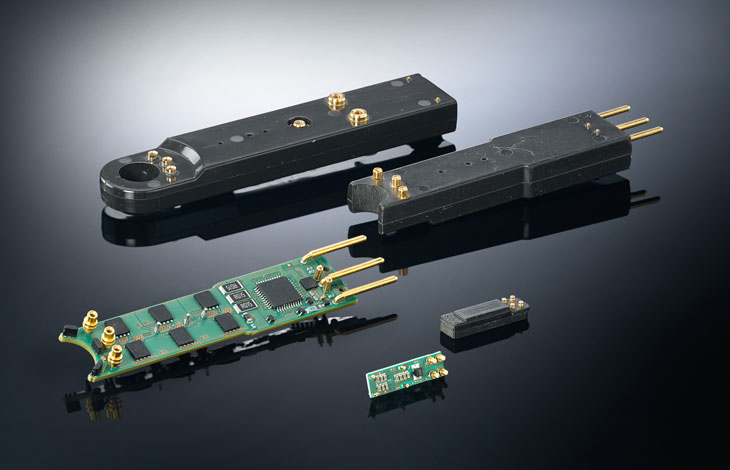

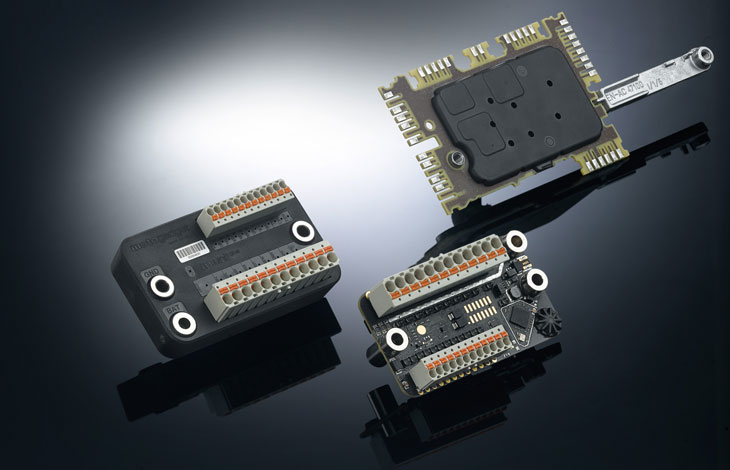

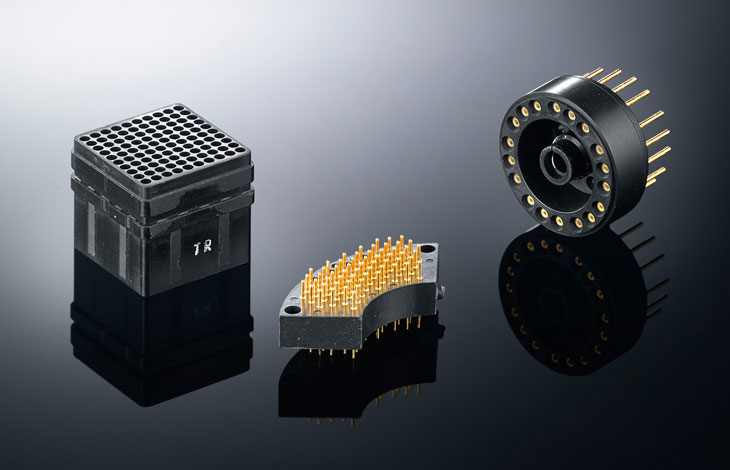

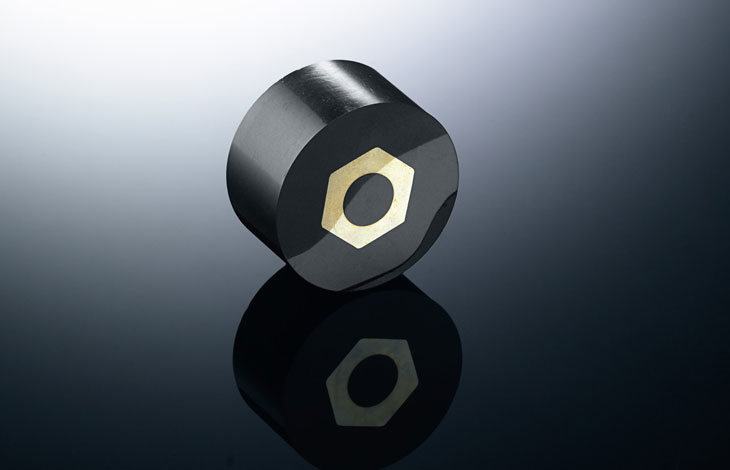

Epoxy resin moulding compounds are ideally suited to encapsulate electrical or electronic inserts/components gently and media-tight. In many applications, such as PCBAs, special underfillers are not required.

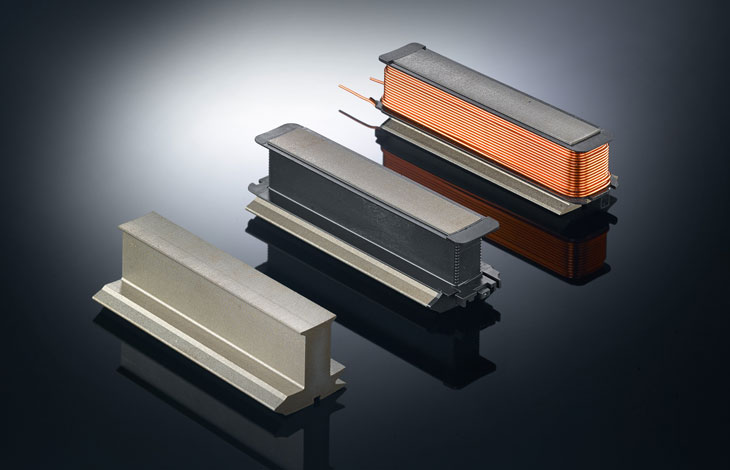

EPOXIDUR® materials make a significant contribution to advancing e-mobility. Thermally conductive, but electrically insulating EPOXIDUR® moulding compounds can be used to produce rotors and stators which have excellent thermal management of the components, resulting in good energy efficiency.

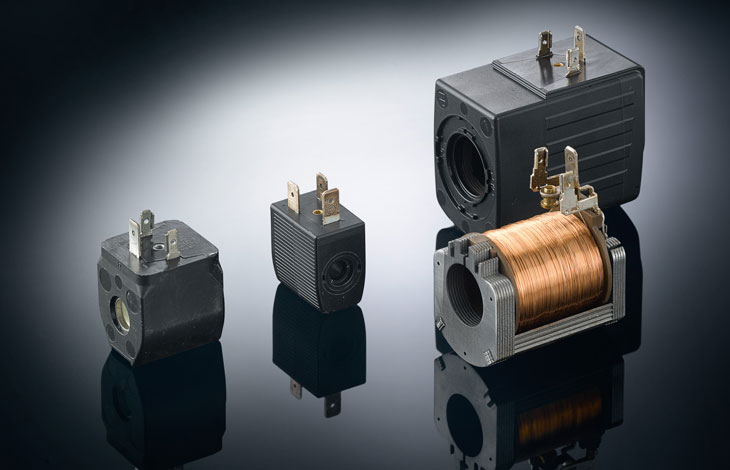

Our moulding compounds are used in a wide range of applications in health technology such as electronic encapsulation and dental surgery applications. They are also very popular as embedding material for microscope technology for minimum gap formation and highest surface quality. They are suitable for overmoulding electromagnetic coils for automation technology and fluid technology or for sensors such as position sensors, speed sensors, position sensors or filling level sensors. An important and frequent application are PCB encapsulations for e.g. TCU’s, ECU’s, control boards and board-bound sensors, furthermore also as electrical connectors for high temperatures in aerospace and plant engineering in safety-relevant areas. In recent applications our epoxy resin moulding compounds are used as power modules (DBC’s) for e.g. renewable energies and automotive engineering.

| Medial-tight lead frame overmoulding |

PCB encapsulation |

Sensor overmoulding | Armature shafts/ slip rings | Smart BLDC |

Electro- magnetic coils |

Metallurgy/ embedding |

Electrical connectors aerospace and military | Rotors & stators | Health technology/ biocompatibility |

Lamp sockets H-4 / H-7 |

|

| EPOXIDUR® EP 3162 E |

● | ● | ● | ●●● | |||||||

| EPOXIDUR® EP 3161 E |

● | ●● | ●● | ● | ●●● | ●●● | |||||

| EPOXIDUR® EP 3163 E |

●● | ●● | ● | ●● | ● | ●●● | |||||

| EPOXIDUR® EP 3580 T |

●● | ●● | |||||||||

| EPOXIDUR® EP 3585 H |

●● | ● | ● | ● | ●●● | ●●● | ●●● | ||||

| EPOXIDUR® EP 3685 T |

●●● | ●● | ●●● | ●●● | ●●● | ●● | ●●● | ●●● | |||

| EPOXIDUR® EP 3681 E |

●●● | ●●● | ●●● | ●●● | |||||||

| EPOXIDUR® EP 3781 E |

●●● | ●●● | ●●● | ●●● | ●● | ●●● | |||||

| EPOXIDUR® EP 3585 S |

●● | ●●● | ●● | ||||||||

| EPOXIDUR® EP 3582 S |

●● | ●● | |||||||||

| EPOXIDUR® EP 3581 L |

●● | ● | ●● | ● | |||||||

| EPOXIDUR® EP 3573 S |

●●● | ||||||||||

| EP 3505 | ●●● | ||||||||||

| EN 5004 | ●●● |

This table is not intended to be exhaustive. Our experts will be pleased to help you select the optimal product for your application.

Should your search for a product for your application not be successful, please do not hesitate to contact us. If required, we offer the possibility to design an individualised and tailor-made product together with you.

| Product name | Technical Data Sheet | UL Yellow Card |

| EPOXIDUR® EP 3162 E | TDB | UL Yellow Card |

| EPOXIDUR® EP 3161 E | TDB | – |

| EPOXIDUR® EP 3580 T | TDB | UL Yellow Card |

| EPOXIDUR® EP 3585 H | TDB | UL Yellow Card |

| EPOXIDUR® EP 3685 T | TDB | – |

| EPOXIDUR® EP 3681 E | TDB | – |

| EPOXIDUR® EP 3585 S | TDB | UL Yellow Card |

| EPOXIDUR® EP 3582 S | TDB | UL Yellow Card |

| EPOXIDUR® EP 3581 L | TDB | – |

| EPOXIDUR® EP 3573 S | TDB | – |

| EP 3505 | TDB | UL Yellow Card |

| EN 5004 | TDB | – |